Are you wrestling with scattered items, tight storage space, and cluttered aisles in your warehouse? The disorganization can lead to wasted time, damaged goods, and frustrated staff. Thankfully, an industrial metal shelving system is the remedy! By investing in heavy duty and adjustable options, you’ll streamline operations and finally conquer the chaos.

A heavy duty shelving unit in a warehouse solves storage problems by optimizing vertical space. This shelving system offers sturdy construction, balanced load capacity, and efficient organization for pallet rack or non-palletized goods. It’s easy to adapt with adjustable shelves, providing versatile storage solutions. Overall, it boosts warehouse efficiency, safety, and productivity by keeping goods neatly arranged and easy to access.

Why Does an Industrial Warehouse Need Heavy Duty Shelving?

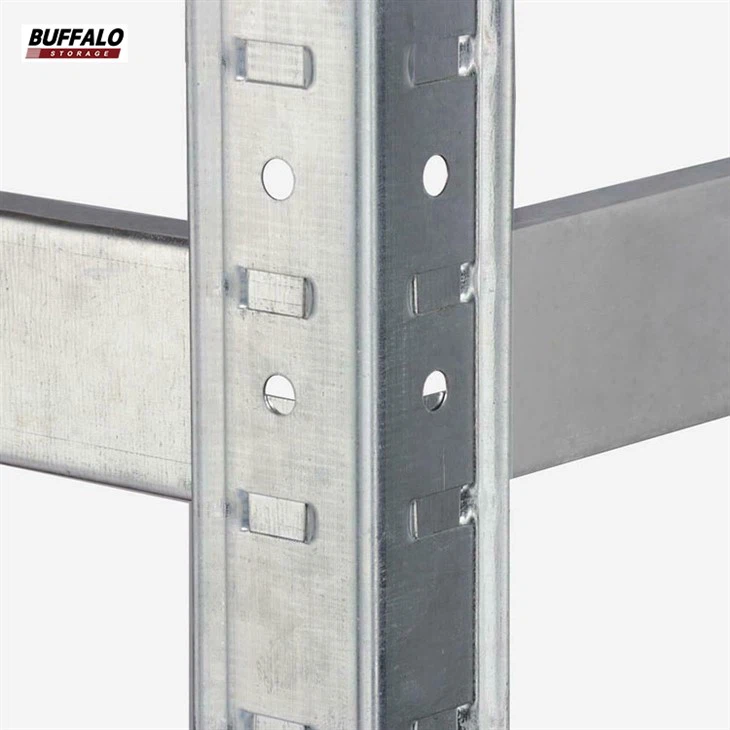

Warehouse operations usually handle heavy loads, repetitive stacking, and frequent traffic from a forklift or pallet dollies. Consequently, heavy duty shelving is not just a luxury but a necessity. Such a shelving system may feature steel shelves, metal shelves, or commercial metal shelving. In fact, many systems use industrial steel or heavy-gauge steel for ultimate strength and durability.

Developing an efficient warehouse depends on the right fitting of industrial shelving systems. These structures handle greater weight capacity—sometimes up to 400 lbs capacity per shelf—and can be customized to your exact capacity requirements. According to one case study, heavy duty metal shelving can reduce labor costs by 20% while optimizing your overall range of industrial storage. By incorporating a rack or two of high-performance metal shelving systems in your warehouse rack layout, you create a safer, more efficient warehouse environment.

Choosing the Right Pallet Rack vs. Rivet Shelving

Choosing the right type of rack is often pivotal in designing a warehouse. Two major varieties come up frequently: pallet rack and rivet shelving. Each offers unique advantages:

| Factors | Pallet Rack | Rivet Shelving |

|---|---|---|

| Load Capacity | Higher capacity to hold heavy loads (ideal for bulk storage) | Supports medium to heavy items; good for non-palletized goods |

| Assembly | Often requires extra hardware, but suitable for forklift usage | Easy to assemble with boltless design |

| Common Use | Best for shipping and distribution centers with lots of pallet movement | Perfect for smaller warehouses or varied item sizes |

Pallet rack designs can support large volumes of pallet loads and can be integrated with wire decking to ensure stability. Rivet shelving, on the other hand, typically uses a boltless shelving approach, ensuring easy assembly and reconfiguration.

When deciding, measure your capacity to hold inventory, gauge your average weight capacity, and think about how frequently you’ll use a forklift to move goods. For example, an industrial warehouse with large volumes of the same product might benefit from pallet rack setups, whereas a smaller storage facility that handles various product sizes might find more versatility in rivet shelving or a hybrid approach.

For more about boltless shelving, check out boltless shelving.

How to Maximize Warehouse Storage Space with a Shelving Unit

Maximizing warehouse storage starts with selecting the right shelving unit. Whether you’re dealing with x 48 or x 30 standard shelf dimensions, tailor the design to your specific inventory. For instance, a storage shelf can be integrated with a rack shelving unit for multi-level usage.

Practical Tips

- Utilize Adjustable Shelves: Seek out adjustable metal or boltless shelving to easily modify the shelf height. This helps fit items of varying sizes and ensures quick reconfiguration as your stock changes.

- Incorporate Starter Bay: A starter bay design is crucial when your warehouse expands. It allows you to assemble and adjust additional sections for growth.

- Plan for Future: Understand your projected capacity requirements. Going too small can lead to early replacement, while an oversized system can waste space.

Using a metal shelving unit with open and closed sections can be beneficial, because open sides allow for quicker loading, while closed backs may provide stability. To explore selections of heavy duty shelving, see heavy duty shelving.

Best Practices for Wire Shelving in a Commercial Metal Shelving Setup

Wire shelving is a popular, lightweight yet durable choice in commercial metal shelving solutions, especially if you handle goods requiring ventilation, such as those in cold storage or mobile storage.

- Prevent Dust: Because the open wiring structure prevents dust buildup, it works well for items sensitive to contamination.

- Safe & Hygienic: Steel wire and metal wire designs allow fluids to drain, thus helping in sanitary conditions, especially crucial for food or pharmaceutical goods.

- Strength and Durability: Although it looks minimalistic, wire shelving unit implementations often come with heavy-gauge steel frames that maintain high weight capacity.

Case study: A distribution center that switched to wire shelving reported a 15% decrease in cleaning hours and improved airflow around products. By extension, they experienced fewer temperature-related spoilage issues and easier item picking.

Using Boltless Shelving and Wire Decking for Efficient Warehouse Shelving

For efficient warehouse management, boltless shelving stands out for effortless setup and quick modifications. Pairing it with wire decking further improves rack stability and reduces the chance of spilled items. Many facility managers appreciate the easy assembly and minimal tools required.

When you shelve items using boltless shelving, you enjoy faster changes in shelf levels, a critical factor for rotating seasonal goods. Additionally, configuring a rack storage plan with wire decking allows overhead lighting to penetrate deeper, boosting visibility and safety. Explore more on advanced boltless shelving systems at boltless shelving system.

Benefits:

- Available in a variety of widths and depths (such as x 24″d x or x 18 standard measurements)

- Ideal for non-palletized or smaller goods

- Facilitates better organization in an industrial warehouse setting

FAQs About Shelve, Warehouse, and Rack Storage

Below, I’ve compiled some frequent questions about ways to shelve your warehouse effectively and manage your rack storage. Let’s clear up doubts to improve your decision-making process.

How many items can a single shelving unit hold?

It depends on the weight capacity, the dimension specifications (like x 30 or x 48), and the type of materials. Generally, a heavy duty system with heavy-gauge steel frames can hold up to 800 lbs or more per shelf.

Is wire shelving good for a cold storage environment?

Absolutely. Wire shelving improves airflow and prevents dust buildup, making it suitable for cold storage and other sanitary environments. Its lightweight yet durable design also works well for frequent rearrangements.

Can I combine pallet rack and rivet shelving in the same warehouse?

Yes! Many managers merge pallet rack to handle large pallet loads alongside rivet shelving for smaller or irregularly shaped goods. This balanced approach suits diverse inventories within an industrial warehouse.

What if I need more storage space later?

Choose a shelving system with adjustable shelves or a starter bay format. Then, you can assemble and adjust or connect additional bays whenever your warehouse inventory expands. This approach supports easy reconfiguration.

Does boltless shelving really handle heavy loads?

Yes. Despite the simpler, boltless design, many systems meet medium duty and heavy duty demands. Always check load ratings, but rest assured that such designs thrive in complex warehouse storage scenarios.

Should I invest in overhead rack storage?

Yes, if you need to free up valuable floor space. Overhead rack or shelf additions can go above workstations. Just confirm that your warehouse meets the required safety codes and that the overhead structure can handle your capacity requirements.